Product Description

Quick Overview

- Timer/RPM Based Output (+12V)

- Engine Speed Tach Input

- Time Based Nitrous Control

- RPM Based Nitrous Enable

- MPH Based Nitrous Enable

- Harness and Sensors Included

Details

There are few Nitrous Controllers on the market that can come close to the feature set offered by the Lingenfelter Performance Engineering NCC-002 Nitrous Control Center. The NCC-002 is capable of controlling up to four stages of nitrous if the fuel supply is controlled by the ECM or other method, with many different available triggering and disabling input options available for each. The NCC-002 controller interface is designed for ease of use and access at the track as all of the settings and options available in the NCC-002 software program are also available on the controller itself. The NCC-002 controller also features enough internal memory to save three user-defined nitrous programs for quick access in the case that track conditions change and a different setup is desired.

While the NCC-002 Nitrous Control Center can be installed into virtually any vehicle, it was especially designed for late model EFI vehicles. Special attention was paid to integrating the NCC-002 into GM LS powered vehicles including:

1998-2002 Camaro

1997-2013 Corvette

2010-2013 Camaro SS2004-2006 Pontiac GTO

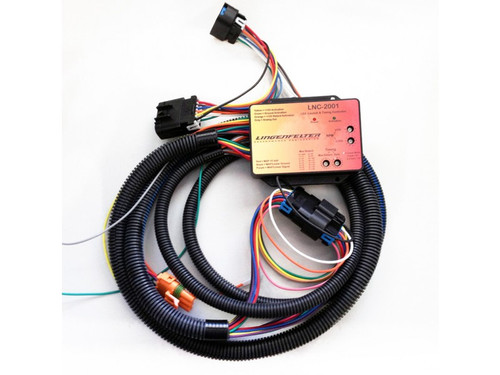

The NCC-002 NOS Controller does not include the harness or sensors which can be purchased separately if you want them. Scroll down to the bottom of this page for related items. The harness is color coded and each wire is clearly marked for each device.

The features alluded to already, as well as the numerous other features listed in the following section, make the NCC-002 Nitrous Control Center from Lingenfelter Performance Engineering one of the most advanced Nitrous Controllers available while still offering the ease of use that renders it practical for seasoned race veterans and weekend racers alike.

Two independent progressive stages of nitrous and fuel

Independent control of both nitrous and fuel duty cycle for each stage

Timer/RPM based output (+12V)

Relay output (+12V) - programmable based on any combination of: Arming input, clutch input, shift input, TPS%, AFR, Nitrous1 %, Fuel1 %, Nitrous2 %, Fuel2 %, RPM, MPH, Fuel PSI, Nitrous PSI

Relay output (Ground) - programmable based on any combination of: Arming input, clutch input, shift input, TPS%, AFR, Nitrous1 %, Fuel1 %, Nitrous2 %, Fuel2 %, RPM, MPH, Fuel PSI, Nitrous PSI

Shift light output, +12 volt

Analog voltage output, programmable - for sending to a data acquisition system or to an ECM for external fuel or spark control. Also can link to the LNC-2000 for progressive timing retard on GM LSx V8 engine vehicles

PWM output for future features - not currently enabled in the software

5 volt and ground output for Fuel Pressure and Nitrous Pressure sensors for improved signal accuracy

Arming input Ground or +12 volt selectable

Clutch input - for clutch switch or WOT switch enable input Ground or +12 volt selectable

Shift input - for gear position Ground or +12 volt selectable

Nitrous bottle pressure input, 0-5 volt

Fuel pressure input, 0-5 volt

AFR input, 0-5 volt

TPS input - accepts rising and falling voltage signal sensors, 0-5 volt

Two analog inputs - accepts rising and falling voltage clutch position sensors, 0-5 volt

Frequency input vehicle speed, possible other inputs later

Software enable/disable pull-up resistor on frequency input

Engine speed tach input

Software enable/disable pull-up resistor on tachometer input

Time based safety over-ride

Fuel pressure safety over-ride

Air fuel ratio safety over-ride

Closed loop bottle heater control using relay output and nitrous pressure input

Time based nitrous control

RPM based nitrous enable

MPH based nitrous enable

Gear position based nitrous enable

Independent Stage 1 and Stage 2 delay adjustments

User configurable between Hold & Wait or full reset when activation is removed and re-enabled. Hold & Wait resumes the progressive system at the point where the system was disabled for example, where the throttle was released

Independent Stage 1 and Stage 2 nitrous and fuel resume ramp rates

Independent Stage 1 and Stage 2 fuel advance settings that allow you to fine tune the system so that the low pressure fuel is delivered to the engine at the same time or before the high pressure nitrous, helping reduce the

chances of initial lean spikes when each stage of nitrous is activated

Multiple solenoid frequency settings independent for Stage 1 & 2

PC programmable via USB interface and Windows XP, Vista or 7

No PC required - can be programmed at the unit

Saves three (3) different programs user settings on the unit

Built in display to view inputs, outputs and settings

Data logging built in PC required to read and view data. All channels logged at 100 samples second. 25 second logging time

Nitrous user settings stored in each data log for ease of recalling past nitrous settings

Free software updates PC & Internet access required

Improvements from discontinued NCC-001 Nitrous Controller

Increased maximum from 20 amps per nitrous & fuel solenoid output to 30 amps on the NCC-002 PN L460240000

The NCC-002 is rated at a total combined maximum solenoid current draw for all four outputs 2x nitrous, 2x fuel is 60 amps

For applications that need more than 30 amps per channel or 60 amps total, external relays should be used

Suggested relays are the Hella solid-state relays PN HELLAH41773001

Solid state relay offer much faster switching than a mechanical relay

This relay is rated at 20 amps continuous duty but can handle much higher current loads for short periods of time like 10-20 seconds as seen in drag racing or standing mile use